The morning after Santa finishes that annual worldwide delivery, his toil is met with not only joy and laughter, but also sheer and utter frustration felt by those charged with assembling those holiday wishes-come-true. It should come as no surprise that Christmas Day is the 24-hour period when I observe the largest flurry of user assistance-related Tweets.

The morning after Santa finishes that annual worldwide delivery, his toil is met with not only joy and laughter, but also sheer and utter frustration felt by those charged with assembling those holiday wishes-come-true. It should come as no surprise that Christmas Day is the 24-hour period when I observe the largest flurry of user assistance-related Tweets.

When depicted in Christmas cards and motion pictures, the presents Santa leaves under trees are fully assembled and easy to learn to use – toy fire trucks, rag dolls, rocking horses. But, the fact is the toys today are sophisticated and technologically complicated, packaged in a compressed form to save on shipping and labour costs, as well as maximize retailer shelf space.

Young, impatient gift recipients will usually attempt to assemble the toy on their own upon unwrapping, but often an adult has to finish the task.

In all the Christmas Day retweets last year, I was disappointed by the complete lack of user assistance innovation – I am expecting no improvement this year. Manufacturers make the effort to engineer products in such a way that they fit into exceptionally small packages, yet see no problem with weighing that same package down with bulky paper assembly instructions in 12 languages. “Innovation” seems to stop at hotlines on the manufacturer level and at paid assembly assistance service on the retailer level.

In all the Christmas Day retweets last year, I was disappointed by the complete lack of user assistance innovation – I am expecting no improvement this year. Manufacturers make the effort to engineer products in such a way that they fit into exceptionally small packages, yet see no problem with weighing that same package down with bulky paper assembly instructions in 12 languages. “Innovation” seems to stop at hotlines on the manufacturer level and at paid assembly assistance service on the retailer level.

I pondered several questions last year as I sipped my eggnog and reflected on the Tweets, and the answers to these remain elusive this year:

- Are trained technical communicators developing this assistance?

- Are engineers and legal high-jacking the assistance with their content?

- Why are we still so reliant on only paper and text?

- Are there any standards that can be used to enforce better quality assistance?

- Why are technical communication institutes and societies not policing their own?

We have many novel methods of providing assistance at our disposal today (and I do not have augmented reality in mind). Why are manufacturers not adopting them? Instead of paper instructions, customers could scan a graphic or icon (anything but a QR code) with a tablet or smart phone camera to get an interactive multidimensional (sounds/pictures/text) assembly experience. Instead of hotlines, they could take advantage of real-time video chats like the new Google Helpouts. So, in 2014 I would like to see more effort put into weaning companies off offering paper instructions, and customers off of having to follow them.

We have many novel methods of providing assistance at our disposal today (and I do not have augmented reality in mind). Why are manufacturers not adopting them? Instead of paper instructions, customers could scan a graphic or icon (anything but a QR code) with a tablet or smart phone camera to get an interactive multidimensional (sounds/pictures/text) assembly experience. Instead of hotlines, they could take advantage of real-time video chats like the new Google Helpouts. So, in 2014 I would like to see more effort put into weaning companies off offering paper instructions, and customers off of having to follow them.

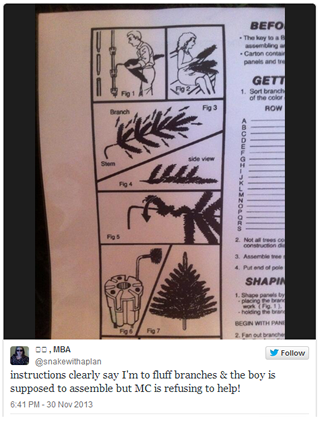

Recently there have been bursts of tweets as people put up their trees and decorations in preparation for Christmas. What stands-out the most in the photos people upload is not the usual unclear steps and strange diagrams, but the complete disconnect between marketing and technical communications departments. How can the assembly instructions for an artificial Christmas tree not have a festive look and feel? I realize people want to get the tree up and start decorating as quickly as possible, but the assembly experience can be made more enjoyable. And the assembly experience is a key part of the overall customer experience, which drives the reason manufacturers are in business.

Recently there have been bursts of tweets as people put up their trees and decorations in preparation for Christmas. What stands-out the most in the photos people upload is not the usual unclear steps and strange diagrams, but the complete disconnect between marketing and technical communications departments. How can the assembly instructions for an artificial Christmas tree not have a festive look and feel? I realize people want to get the tree up and start decorating as quickly as possible, but the assembly experience can be made more enjoyable. And the assembly experience is a key part of the overall customer experience, which drives the reason manufacturers are in business.

Instructions offer manufacturers a post-purchase captive audience and an opportunity to both help customers get the product assembled, and reinforce that they made a good buying decision. Rather than treating instructions like an external, almost foreign element (and bad translations add to that), companies should look at them as a key feature of every product they sell—and so their calibre reflects on the product’s overall quality.

Instructions offer manufacturers a post-purchase captive audience and an opportunity to both help customers get the product assembled, and reinforce that they made a good buying decision. Rather than treating instructions like an external, almost foreign element (and bad translations add to that), companies should look at them as a key feature of every product they sell—and so their calibre reflects on the product’s overall quality.

The only effort I have seen so far is by Ikea in their gingerbread house assembly instructions – the well-known Ikea man in a Santa hat.

The only effort I have seen so far is by Ikea in their gingerbread house assembly instructions – the well-known Ikea man in a Santa hat.

So this Christmas Day morning, I encourage you to pay extra attention to the assistance that accompany your gifts, and share the good and bad ones on Twitter using the hashtag: #xmasassembly

Let’s get that hashtag trending on the December 25th!

|

|